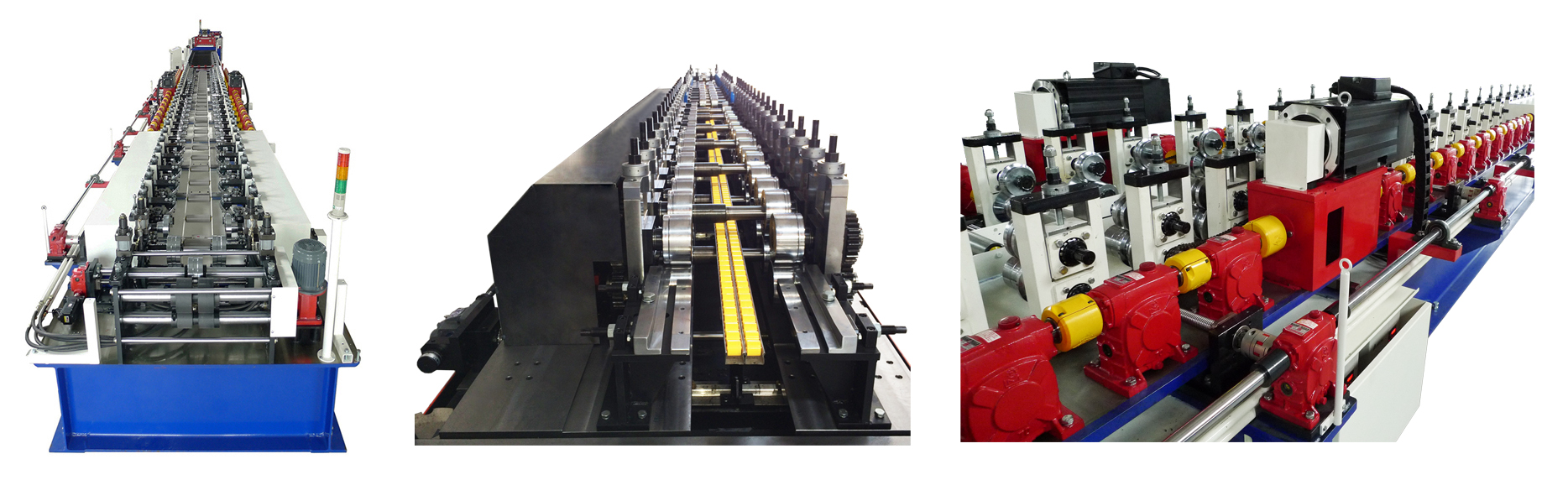

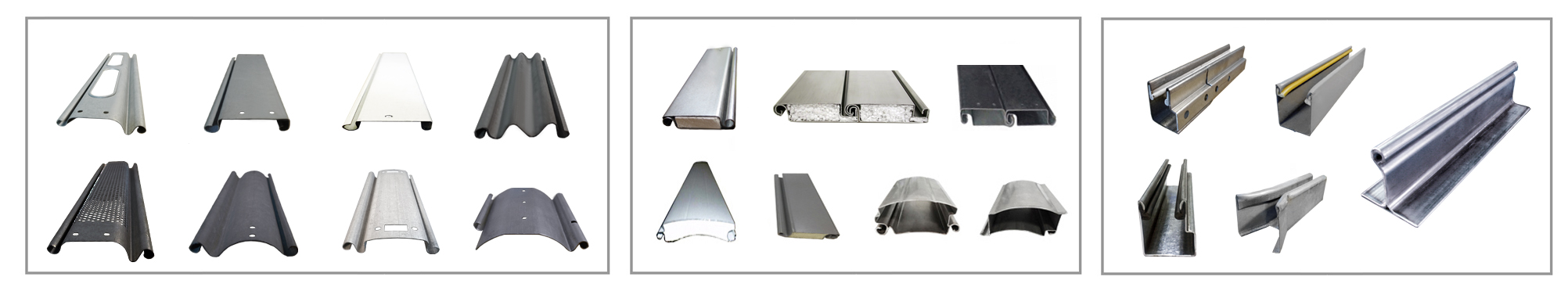

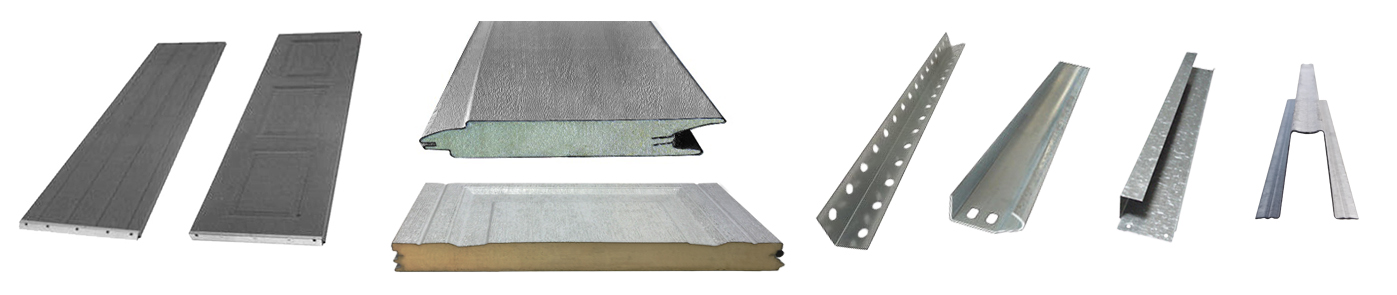

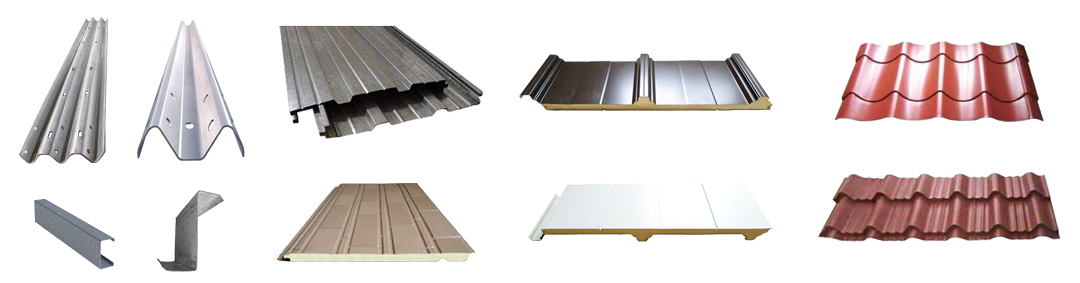

SEAHOW Rollforming System serves in multiple industries to manufacture various applications. We are experienced with the critical criteria thus capable to design powerful, reliable, efficient, and balanced machine for your desired performance and budget.

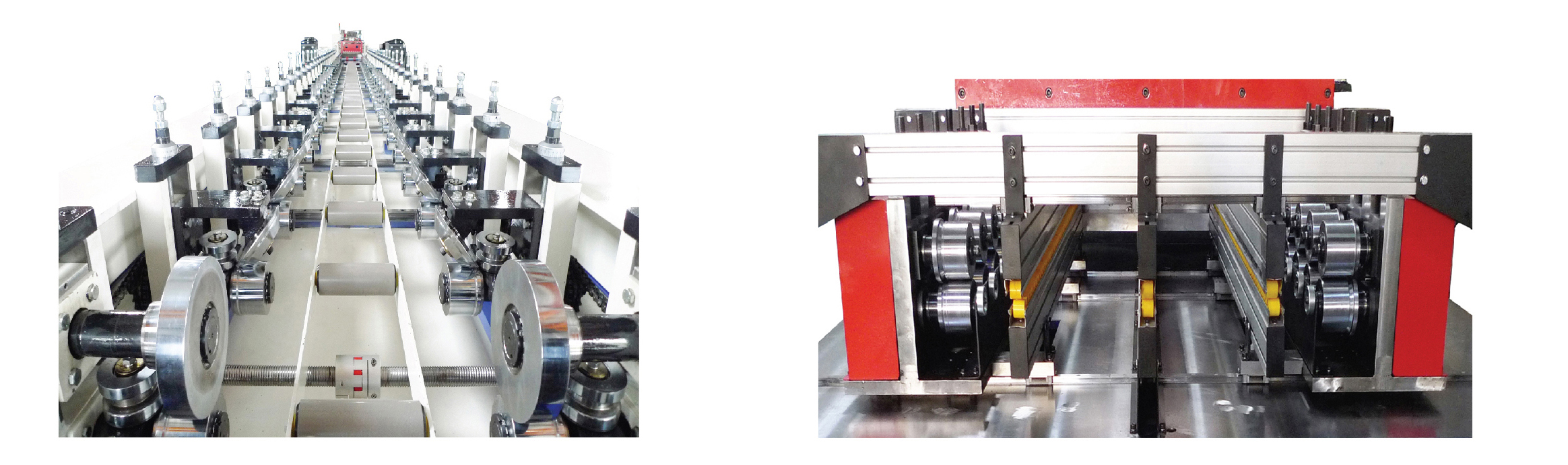

We have made numerous upgrades accordingly to the input and perspective from our customers in various industries. We have standardized many features in our roll forming systems to maximized productivity, efficiency, and durability.

We are capable of rollforming ferrous materials of steel, galvanized steel, and stainless steel of various thickness. Non-ferrous material such as aluminum, brass, and copper are also available.

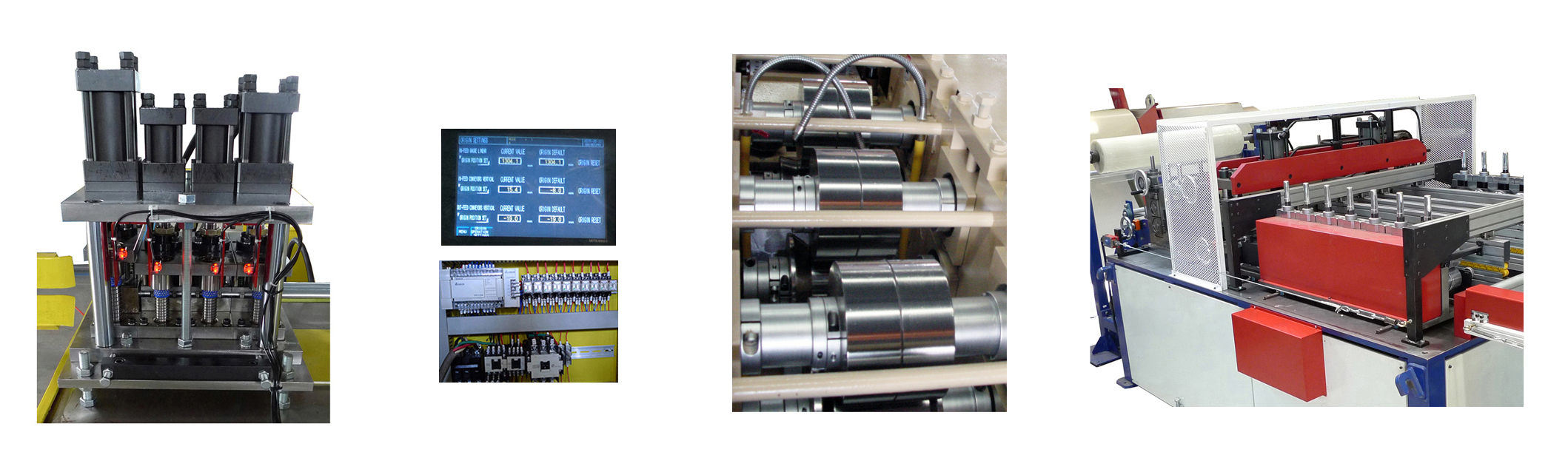

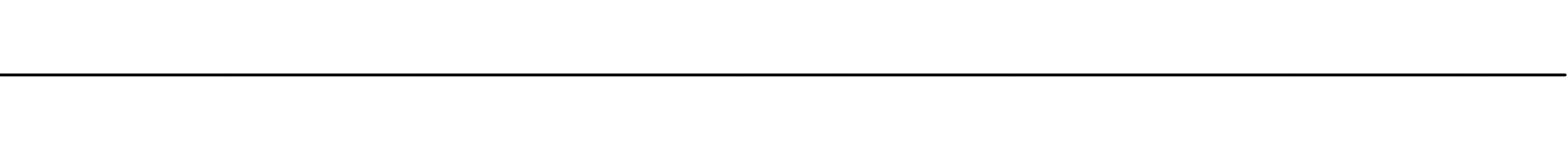

Now featuring dual cantilevered duplex system for "Dynamic Width Adjust". Utilizing high quality, high precision ball screws paired with Servo Motors, the rollformeing system can adjust to desired width via simple control on a touch screen. This step-less, variable width adjusting eliminates the traditional method of inserting spacers across all forming stations which can take up to hours of valuable production time.

Please visit Full Manufacturing Line section to see more specific applications.

We are capable of incorporating various machineries with our rollforming system into a full automatic / semi-automatic production line.

( We reserve the right to modify the technical details and data listed above as a result of ongoing, technical improvement programs. )

( We reserve the right to modify the technical details and data listed above as a result of ongoing, technical improvement programs. )