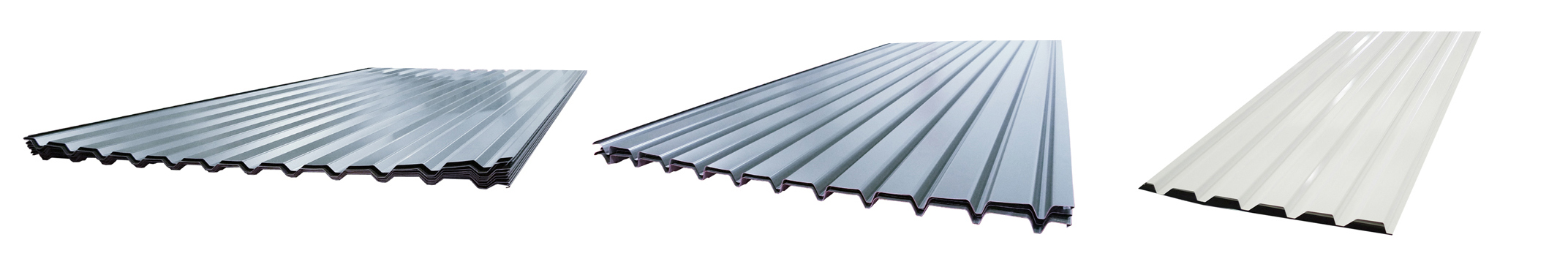

When producing roller door sheet, a traditional rollforming machine would be the most efficient and ideal choice. However due to the wider width of the roller door sheet, the corrugated sheet may suffer from minor bowing effects and deformations. The dedicated machine would also be limited to one specific profile or shape.

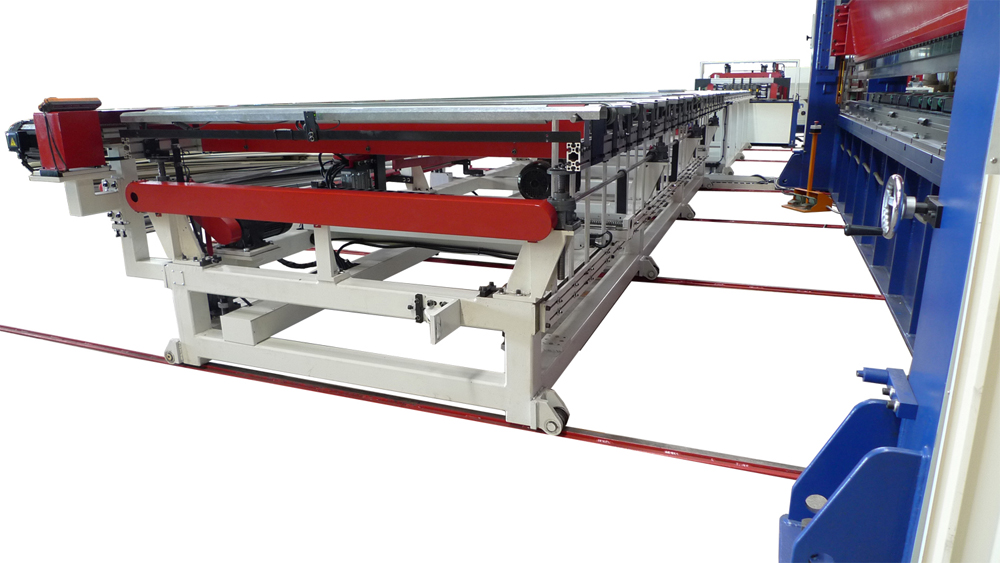

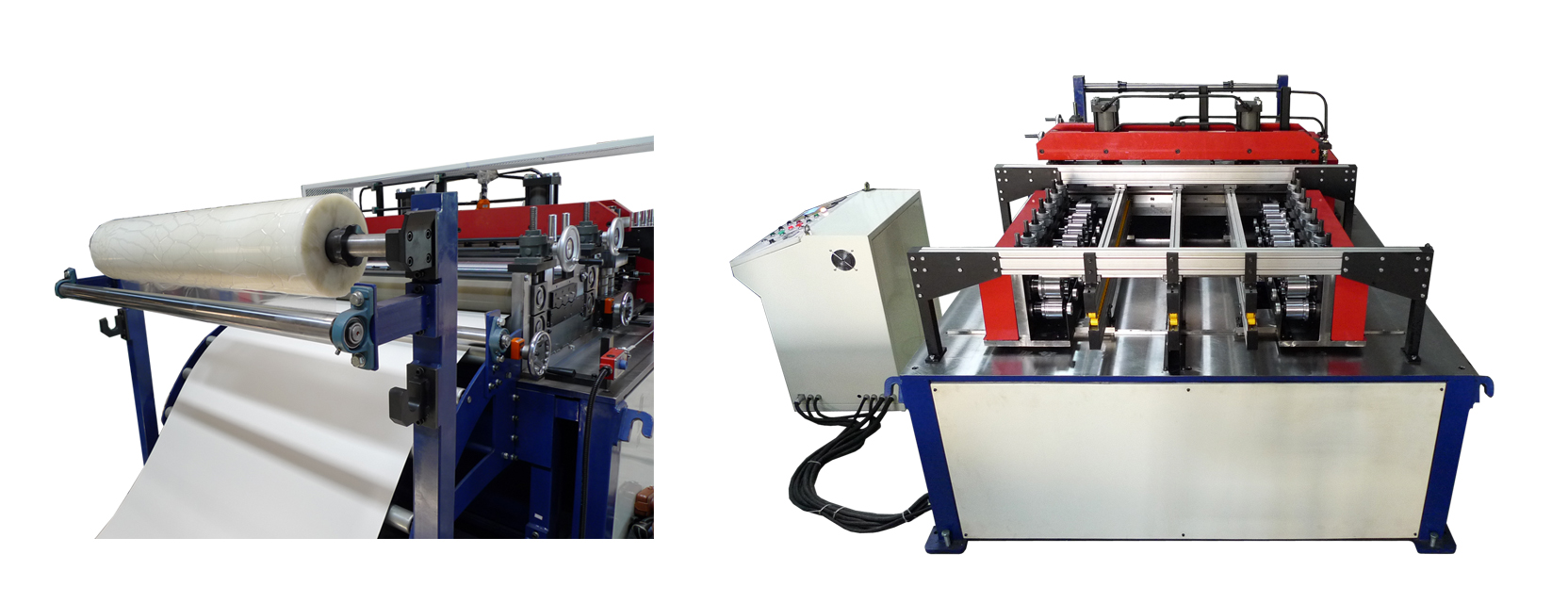

The automatic roller door manufacturing line we have developed begins the process with our fully automatic rollforming system with dynamic width adjust about center line, to roll form the sheets with open lock seam varying in width. The desired width of the sheet can quickly be adjusted within seconds via a colored touchscreen. The open lock seam sheet is then transported downstream via a motorized roller table to the pop-up conveyor in-feed system of the hydraulic press brake.

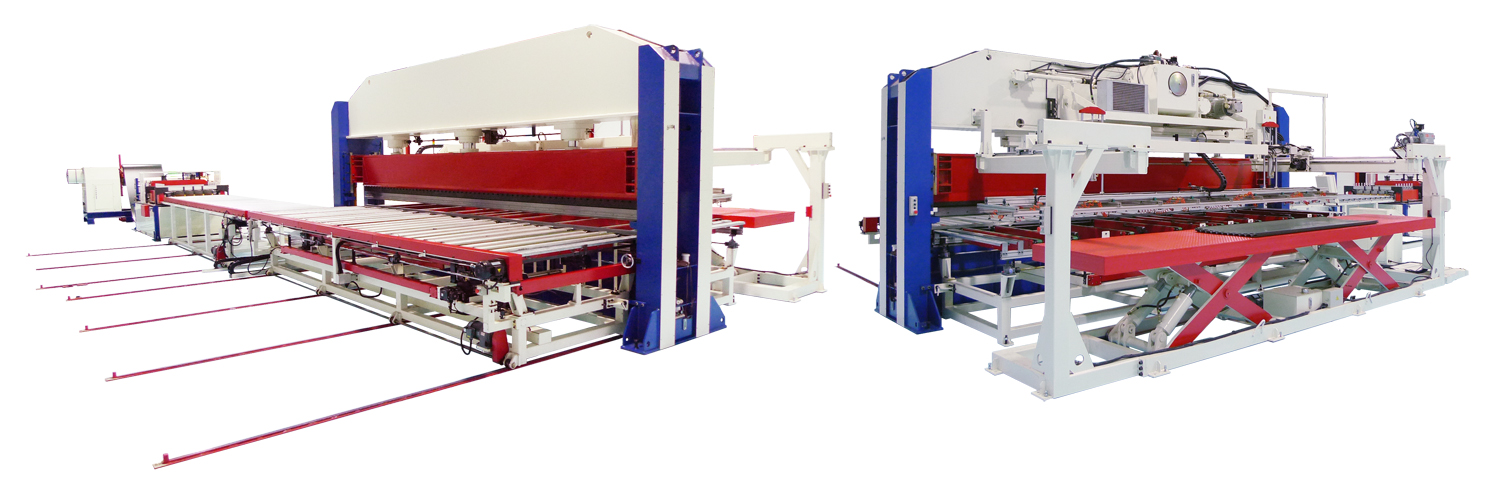

We utilize a hydraulic press brake with triple cylinders, paired with bottoming punch & die set. The nature of the press brake punch and die set also allows smaller radius in the bend versus forming rollers of rollforming machines. This ensures each corrugation to be very well defined both structurally and esthetically.

.jpg)

The pitch of each corrugation is automatically calculated evenly, based on the width of the sheet and the appropriate punch & die set. The toolings are fastened with hydraulic clamps to allow quick changing of multiple styles within minutes. Once all the corrugations are completed it gets lifted off via pneumatic vacuum re-claimer and be placed on a height-sensing platform.